Plastic Materials and Environmental Externalities: Structural Causes and Corrective Policy

Flores, Mario C.

Georgia Institute of Technology Undergraduate Atlanta, Georgia, USA

Abstract

Several negative externalities arising from the consumption and disposal of plastics materials are described. Such externalities include the aesthetic damage created by landfills containing plastic waste, the impact to marine life of plastic residuals, the hazardous emissions of plastic incineration, and the economic inefficiencies created by the difficulty of plastic reutilization from recycling. The fundamental causes for the presence of these externalities are explored, including the lack of incentives in present legislation for the development of a recycling infrastructure and fluctuating market conditions for recycled input materials. A corrective policy is then presented which aims to internalize the costs of recycling and to promote R&D activities into the development of efficient, low-contaminant recycling facilities in the US.

Citation

Plastic Materials and Environmental Externalities: Structural Causes and Corrective Policy. Flores, Mario C. . Lethbridge Undergraduate Research Journal. Volume 3 Number 2. 2008.

Plastic Materials and the Environment

Plastic materials have revolutionized the consumption of durable goods and virtually all major manufacturing industries in the United States. From 1960 to 2000, the volume of production and consumption of plastics in the US increased by a factor of 13. [1,2] The impact of plastics is derived from their numerous desirable properties for materials used in products ranging from milk jugs to water pipes to microprocessor packages. Such diverse applications result from plastic material properties such as resistance to chemical and environmental degradation, tunable optical properties, ease of shaping and molding, dependence of mechanical and thermal properties on degree of cross-linking, and temperature dependence of plasticity and flow properties. Furthermore, the ability to safely produce several types of plastics has contributed to the development of high-volume manufacturing facilities capable of producing millions of tons of plastic products per year. [1,2] The combination of the desirable properties of plastics and feasible plastic production processes has led to the development of thousands of products, which have benefited modern society through the direct and indirect creation of millions of jobs and the creation of markets with important contributions to the world's economic output.

Along with the many benefits that modern society has obtained from plastic production and consumption, the high degree of household refuse and industrial disposal of plastic materials causes a significant level of environmental concern. [1,2] Furthermore, negative externalities of significant proportions are created by the difficulty of plastics recycling and the damaging decomposition mechanisms typical of many biodegradable plastics [1,2] Plastics constitute approximately 11.8% of the weight of municipal solid waste (MSW). [4] In 1995, ~57% of MSW was disposed in landfills and ~16% was incinerated in waste-to-energy processing plants. [1] The aesthetic damage created by landfills and the hazardous emissions resulting from incineration are two examples of undesirable effects from the inefficient management of plastic waste. Externalities such as these result from failing to internalize costs associated with inefficient recycling.

More specifically, the most important externalities created by inefficient plastic disposal include the aesthetic damage created by landfills containing plastic waste, the impact to marine life of plastic residuals, the hazardous emission of plastic incineration, and the economic inefficiencies created by the difficulty of plastic reutilization from recycling. [1,2] If effective policies are to be implemented with the purpose of reducing or eliminating the negative externalities from plastic waste, the aesthetic, ecological, social, and economic aspects of plastic waste management must be studied.

Aesthetic Damage of Plastics

The disposal of plastics in landfills creates a serious aesthetic problem in large urbanized areas of the world. The chemical stability of plastic prevents plastic waste from decomposing into the environment at a rate comparable to the rate of waste generation. As plastic waste accumulates in urbanized areas, values of surrounding properties fall. Furthermore, consumer waste in beaches, highways, and parks creates a negative externality for tourists in public areas. In the long run, the incentive to preserve the local environment is reduced and the costs of cleaning and recovery of contaminated sites rise. Large streams can also transport excess plastic waste to other areas creating a mobile contamination problem.

Impact to Marine Life

Plastic waste comprises 60% to 80% of marine debris litter accumulated in ocean shores. [1] Plastic residuals ranging from microscopic polyethylene particles to large floats, crates, and netting ropes from fishing operations are also present in the world's oceans. The problem of marine waste is aggravated by the low reliability of removal mechanisms aimed at reducing marine plastic residual concentration in the oceans. [1] Effects on marine life of plastic waste include the entanglement and ingestions of harmful plastics by marine vertebrates and the bioaccumulation of toxicants causing reduced reproduction capacities in certain species. [1]

Policies aimed at reducing or preventing littering along beaches and other marine areas are difficult to formulate due to the complexity involved in obtaining accurate contamination data. In particular, mechanical attrition and photodegradation may cause plastic waste to become brittle, which oftentimes results in plastic breakdown into very fine detritus. [1] This detritus is difficult to observe and quantify, particularly in areas far from beaches. Furthermore, mechanisms by which plastic materials are able to settle on the seafloor are poorly understood, and actually performing observations of plastics settled on the seafloor is very difficult. [1]

Another challenge for the control of plastics pollution in the marine environments is the traditional legislative approach consisting of an excessive reliance on uniform technology-based limits. [3] Such limits do not have a market-based incentive and oftentimes produce inefficient results for both the environment and economic activity. [3]

1.3Hazardous Emissions of Plastics

The release of hazardous emissions from incineration of municipal solid waste (MSW) also creates negative externalities. [1] Combustion of MSW at 22% efficiency can generate 600 kWh of electricity with less CO2 emissions as compared to coal plants. However, gases released from decomposition processes from plastics present in MSW include cyclic chlorinated hydrocarbons believed to be toxic. [1] Specifically, the release of hydrogen chloride and dioxins from PVC incineration can be very toxic to animal species. The corrosive fumes released into the atmosphere from plastic combustion can also increase acidity levels of the environment. A potential effect from such emissions is the generation of acid rain.

Inefficient Plastic Recycling

Arguably the largest market failure resulting from inefficient plastic disposal is the waste in materials and resources resulting from the relatively low recycling rate of plastic materials. As compared to lead-acid batteries and aluminum cans (with recycling rates of ~93% and ~65%, respectively) the recycling rates for plastic bottles has stabilized at ~25%. [4] The steady recycling rate results from yearly increases in the number of plastic bottles used to package a large variety of products. Despite the fact that recycling capabilities increase with time, the increasing amount of plastic bottles in consumer products produces a steady plastic bottle recycling rate.

The decreased demand of products manufactured from previously used plastic materials further decreases the incentive of increasing recycling rates. Furthermore, lack of information and logistical problems in collecting plastic materials also decrease the effective recycling rate. The low plastic recycling rate implies that the great majority of polymer-based materials utilized for plastic bottles enter the waste stream never to be used again. This market failure is particularly important since plastics possess a longer life-cycle than currently achieved with such a low recycling rate. [1]

Plastics Recycling: Law and Economics

The management of plastic materials recycling is regulated by environmental laws at all levels of government. Among the most important laws enacted at the federal level are the Solid Waste Disposal Act (42 U.S.C. 1601 et seq.), the Resource Conservation and Recovery Act (42 U.S.C. 321 et seq.), and the Ocean Dumping Act (33 U.S.C. 1411 et seq.). [5] Laws specific to states and cities contain regulations that overlap with the provisions found in the federal laws. Examples of state environmental legislation include the Georgia Waste Control Law (OCGA 16-7-50) and the Georgia Hazardous Waste Management Act (OCGA 12-8-60). [6] At the local level, nearly all cities have environmental regulations in some form. These include provisions for municipal solid waste (MSW) management and industry-specific recycling regulations.

Environmental Law and Solid Waste: The Solid Waste Disposal Act

The Solid Waste Disposal Act of 1965 is the most comprehensive piece of legislation at the federal level regarding industrial and household solid waste management. Since plastic materials and polymer by-products compose a significant fraction of the industrial waste stream, numerous provisions in this Act attempt to deal with the externalities generated by plastic materials industrial and municipal recycling.

The Solid Waste Disposal Act has as its main objective reducing the negative externalities generated by the disposal of waste. The General Provisions section (Subchapter I) of the law states:

“The Congress finds with respect to the environment and health, that—

(1) although land is too valuable a national resource to be needlessly polluted by discarded materials, most solid waste is disposed of on land in open dumps and sanitary landfills;

(2) disposal of solid waste and hazardous waste in or on the land without careful planning and management can present a danger to human health and the environment;” [7]

After outlining the importance of the environment as it relates to human health, the Solid Waste Disposal Act also defines specific externalities created by inefficient disposal of waste:

“The Congress finds with respect to materials, that—

(1) millions of tons of recoverable material which could be used are needlessly buried each year;

(2) methods are available to separate usable materials from solid waste; and

(3) the recovery and conservation of such materials can reduce the dependence of the United States on foreign resources and reduce the deficit in its balance of payments.” [7]

After defining the objectives of the law and outlining the externalities that solid waste can create, the Solid Waste Disposal Act summarizes the regulations that must be followed while managing hazardous waste in the Hazardous Waste Management section (Subchapter III). This section provides for the definition and classification of hazardous industrial and household waste. The main criteria while defining hazardous waste consists of “toxicity, persistence, and degradability in nature, potential for accumulation in tissue, and other related factors such as flammability, corrosiveness, and other hazardous characteristics”. [7] Special provisions are in place, however, for waste generated from the exploration and development of important raw materials and energy products. Specifically, the Act leaves waste in “drilling fluids, produced waters, and other wastes…associated with the exploration and production of oil and natural gas” under the authority of previous federal and state regulations. Similar provisions are made for the production of waste created from “the combustion of coal or other fossil fuels” and from “the extraction and processing of ores and minerals”. [7] Furthermore, the Act excludes recovery facilities that mass-burn solid waste from the regulations outlined in the Hazardous Waste Management section, provided they burn only household waste that is known to contain no hazardous materials. [7]

The Act recognizes that at a fundamental level the problem of waste disposal and management is an economic issue with measurable effects and consequences in many areas of society. As such, the Act outlines mechanisms through which long-term structural change to the economy of waste disposal can be achieved and managed. The Act provides in the section titled “Research, Development, Demonstration, and Information” (Subchapter VIII) for ways to appropriate financial resources for use in “research, investigations, experiments, training, demonstrations, surveys, public education programs, and studies relating to:

(1) any adverse health and welfare effects of the release into the environment of material present in solid waste, and methods to eliminate such effects;

(2) the operation and financing of solid waste management programs;

(3) the planning, implementation, and operation of resource recovery and resource conservation systems and hazardous waste management systems, including the marketing of recovered resources;

(4) the production of usable forms of recovered resources, including fuel, from solid waste;

(5) the reduction of the amount of such waste and unsalvageable waste materials;

(6) the development and application of new and improved methods of collecting and disposing of solid waste and processing and recovering materials and energy from solid wastes;” [7]

Since the enacting of the Solid Waste Disposal Act in 1965, many challenges related to the management of plastic waste have emerged with the increase in economic output of the last three decades. Furthermore, the main objective of the Act of effectively managing solid waste in the United States provides for a framework to deal with the burden of reducing the negative externalities created by mismanaged solid waste, particularly plastic waste.

Despite the emphasis given to acquiring financial resources for the purposes of “Research, Development, Demonstration, and Information” for efficient use of plastics in the United States, there are serious inefficiencies observed in the Solid Waste Disposal Act and the Resource Conservation and Recovery Act as related to the promotion of the efficient use of plastics resources. These inefficiencies result from the lack of market incentives to increase recycling rates of plastic products. For example, the responsibility of performing the necessary research and development for the efficient use of plastics is left as a task for the federal government agencies. There is no mention of specific fiscal, monetary, or resource incentives for private firms or research institutions engaging in the development of infrastructures for fuel recovered from plastic waste or in the establishing of markets for recycled plastic products.

The Current State of Recycling Economics

The number of US companies involved in plastics recycling activities reached 1,790 in May of 2007. [8] Nevertheless the demand for products from recovered plastics (the majority of them plastic bottles) has risen at a faster rate than the supply of post-consumer bottles recovered from the waste stream. [8] A limiting factor of the recovered plastics markets is the fact that many consumer products such as drink bottles manufactured from PETE (Polyethylene terephthalate) and HDPE (High-density polyethylene) are disposed of shortly after use and never reach a recovering container. This is another cause for the plastic bottle recycling stabilizing at ~25%. [4] Organizations such as the American Chemical Society and the Plastics Division of the American Chemistry Council are creating education campaigns aimed at reducing the externalities from the inefficient disposal of plastics materials, particularly bottles and containers. [8] Other organizations such as the Association of Postconsumer Plastics Recycling (APR) and the American Beverage Association (ABA) are partnering with communities throughout the US to create “All Plastic Bottle Collection Programs” to increase the percentage of plastic bottles that enter recovered product markets. [8]

The economics of recycling is characterized by the competition between recycled materials with virgin materials. [8] The main challenges for the recycling industries are the high fixed costs of recycling processes and the subject of plastic inputs to low prices during periods of slow economic activity. [7] Particularly during economic slowdowns in emerging markets such as Asia and Latin America, the flow of plastic inputs to be recycled in the US declines with respect to the trade in virgin materials. [8] The recycling of plastic bags and plastic components in durable goods such as cars and computers is much more successful than plastic bottle recycling. This is due respectively to the commodity nature of polyethylene in plastic bags and effective legislation such as the Electronic Waste Recycling Act of 2003 in California. [8]

Market incentives aimed at promoting the increase in recycling of plastic materials in the economy can be formulated in terms of job creation, fuel cost savings, and sustainability issues. An example consists of establishing fiscal incentives for the strengthening of vertically integrated manufacturers that use recycled materials as inputs. The Plastics Division of the American Chemistry Council estimates that of the 382 post-consumer plastic reclamation facilities, 265 are vertically integrated into product manufacturing. [4] Subsidies could also promote research and development in the recycling industry with the purpose of increasing post-consumer plastic materials use in the manufacture of fiber, for which 54% of PET recycled material is used an input. [4] Education campaigns on the importance of sustainable practices could also create high returns to investments. By educating plastic producers and consumers about the importance and benefits of plastics recycling, marginal benefits to plastic production could be increased to a high enough level to produce structural change in the plastics industry.

Alternative Policies for Plastics Recycling: Reducing Externalities

Structural Causes of Externalities in Recycling

There are large opportunities available with the improvement of plastics recycling activities in the United States. As mentioned, the rate of plastic bottle recycling has stabilized at ~25%. Increasing this recycling rate could present benefits to plastics producers through improvements in production yields and energy savings, to property owners through the reduction in landfill space occupied by plastics, to consumers by lowering plastic materials prices, and to the environment through the reduction in the impact to marine life and toxic emissions from incineration.

At present the most important barriers to plastics recycling in the United States are the uncertainty in collection and transportation costs, the price volatility of recycled materials, and the influence of the quality on the demand for recycled materials. [9] The uncertainty in collection costs results from the difficulty inherent in separation processes involved in separating plastic waste from MSW. [9] Collection costs also rise as compared to aluminum and glass collection due to the low bulk density of plastics and the relatively low concentration of plastics in the waste stream. [9]

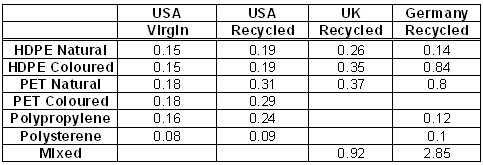

Recycled plastic raw materials also exhibit a higher variance in prices than virgin plastics do. Table 1 shows a comparison between the variance in price of recycled and virgin materials for several types of polymers. The values in the table are given as a ratio of standard deviation of price to mean price.

Table 1: Price Variance of Recycled and Virgin Plastics: USA, UK, and Germany. [9]

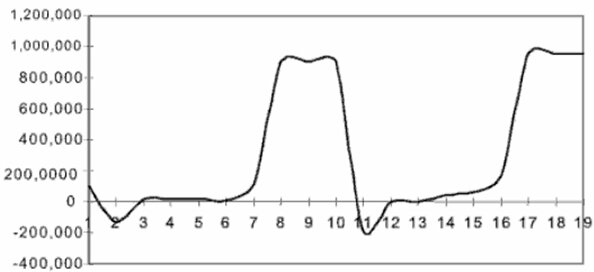

As it is evident from table 1, the variance in price of recycled plastics is higher than virgin plastics. This is an important constraint for the financial and production decisions of recycling companies. Since recycling companies operate with very thin margins, the time spent in obtaining accurate price information can lead to loss of profits, resulting in companies leaving the market. [9] Since the time spent in the allocation of prices becomes considerable, the opportunity cost of engaging in plastics recycling can increase significantly. [9] Even if price volatility does not cause profit loss in the short run, the uncertainty in revenue in the long run may drive recycling companies out of the market. The variations in the profitability typical of reprocessing of plastics are shown in figure 1. This figure includes monthly data for the United States recycling market for the period from 1996 to 1998. Months are indexed from 1 to 19 and the total revenue in dollars is given in the vertical axis. [9]

Figure 1: Profitability of Reprocessing for Recycled Plastics in the US: 1996 to 1998. [9]

Lastly, consumer perceptions of the quality of reprocessed materials as compared to virgin materials induce yet another uncertainty factor in the profitability of recycled materials. This can be characterized as an “information externality” and is the result of “incorrect and irrational” expectations of recycled product quality from the consumer's perspective. [9] Quality issues expectedly arise during recycling processes due to the inherent contamination present in collected plastic waste. Furthermore, quantitative analysis of the effects of contaminants on the quality of intermediate and final products from recycled plastics is very difficult to determine. [9] In markets where consumers of recycled materials have a cold attitude towards risk the potential for profits is compromised and the incentive in large-scale recycling activities is reduced. [9]

Suggested Policy: Improving Recycling through Development of Infrastructure

A critical component of the market failures in recycling consists of technology constraints in the separation and recycling of plastics components, particularly PET and HDPE bottles. [9] As previously mentioned, collection and transportation costs lead to price volatility, which leads to profit uncertainty and recycling companies exiting the market. Some of the technical difficulties involved in the collection of plastics include the specifications of mechanical agitation and heat distortion of plastic films, and the level of non-polymeric contaminants that enter polymer mixtures during extraction.

Several important technological developments have resulted in this area, with many patents granted to individuals and companies performing research into the efficiency of plastic recycling. [10,11] Furthermore, for more significant progress to be achieved in this area, research grants and subsidies could prove to be very beneficial. Callan and Thomas define an environmental subsidy as a “payment or tax concession provided for abatement equipment purchases or pollution reductions”. [3] The abatement equipment in this case would consist of efficient recycling plants that complete recycling operations with less contaminant than presently observed. A government subsidy could therefore be utilized in research and development activities. Once suitable low-contaminant separation processes are developed, similar subsidies could be granted to companies engaging in the implementation of these processes in communities where they are most needed. This could have a positive effect on the efficiency of the 382 facilities devoted to the reprocessing of the post-consumer plastics. [4]

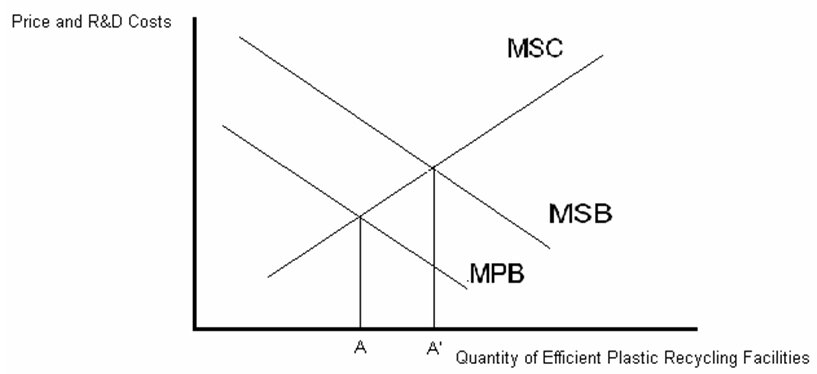

Figure 2 shows a hypothetical subsidy in the market for plastics recycling from the waste stream. In this case, the marginal private benefit (MPB) does not include the benefit obtained from efficient, low-contaminant recycling processes. This benefit can be modeled as a marginal external benefit (MEB). Adding MPB and MEB yield marginal social benefit (MSB).

Figure 2: Environmental subsidy for the market of efficient, low-contaminant recycling facilities in US communities.

In figure 2 the environmental subsidy consists of the vertical distance between MSB and MPB at A'. This subsidy would encourage R&D efforts and facility construction for efficient plastics recycling plants. The intended outcome would be for better recycling processes to encourage consumers to demand more raw materials from recycled plastics products, which would now unambiguously be of the same quality as virgin materials. Furthermore, with novel recycling processes proving to be successful, the price of recycled raw materials could decrease. This would be due to decrease in fixed costs of the operation of recycled plants, which would have greater efficiency.

Several challenges would arise with the attempted implementation of this environmental subsidy. Achieving allocatively efficiency in this market would require complete knowledge of the value of MEB to be denominated as the amount of the subsidy. The MEB computation would require quantification in dollar terms of the benefits to society from the reduction in the externalities discussed in section 1 of this report. Namely, such analysis would require the computation of economic effects of toxic gases released into nature from polymer combustion, negative impact of aesthetic damage of landfills, impact to marine species, and creation of employment, tax revenue, and secondary markets arising with improved plastics recycling. Another important consideration that could prove to be a challenge would be regional differences of the environmental subsidy. Efficiency of recycling varies across the US due to differences in distances and logistic considerations across states and municipalities. Extensive research would be needed to optimally assign subsidies to different institutions and corporations performing research in efficient plastics recycling. However, similar challenges would exist with other market incentives, namely pollution charges, deposit/refund systems, and permit markets.

Conclusion

Inefficient plastic recycling causes several important negative externalities in the US economy. These include, namely, the aesthetic damage of landfills, the impact to marine life, toxic emissions from incineration, and loss of profits from potential recycling markets. Legislation at all levels of the US government attempts to deal with these negative externalities. However, more effective policies are needed to decrease the effects of the market failures resulting from inefficient plastic recycling. Despite the challenges of establishing subsidies and other market incentives as solutions to the problem of inefficient recycling, there are great opportunities for benefiting from more efficient recycling processes. Furthermore, increased research in sustainability challenges clearly points to the need of engaging in reducing externalities in inefficient recycling and other environmental issues.

Acknowledgment

This paper was written as part of course requirements for ECON 4440 - Undergraduate Environmental Economics. This course was taught by Professor Brian Hunt of the Economics Department at Georgia Tech. I would like to express my great appreciation for all his advice and encouragement while completing this paper and other requirements of the course. I greatly enjoyed having him as a professor.

About the Author

My name is Mario Flores and I am a graduating senior at the Georgia Institute of Technology (Georgia Tech) in Atlanta, GA. My major is Materials Science and Engineering. During my last semester as an undergraduate I am completing 5 courses in Economics with the intention of obtaining an Economics Certificate in conjunction with my Bachelor of Science in Materials Science and Engineering.

Endnotes

1. Andrady, Anthony. (2003). Plastics and the Environment. New Jersey: John Wiley & Sons, Inc.

2. Elias, Hans-Georg. (2003). An Introduction to Plastics. Weinheim: Wiley-VCH GmbH & Co. KGaA.

3. Callan, Scott and Thomas, Janet. (1996). Environmental Economics and Management: Theory, Policy, and Applications. Chicago: Irwin.

4. American Chemistry Council, Plastics Division. Plastic Recycling Facts. Retrieved October 16th, 2007. http://www.americanchemistry.com/plastics/

5. Environmental Protection Agency, Laws and Regulations. Introduction to Laws and Regulations. Retrieved November 7th, 2007. http://www.epa.gov

6. State of Georgia Laws and Regulations Website. Retrieved November 7th, 2007. http://www.georgia.gov

7. The Solid Waste Disposal Act. U.S. Code 42 FCR 82. Retrieved November 7th, 2007. http://www.law.cornell.edu/uscode/

8. American Chemistry Council, Plastics Division. State of Plastics Recycling. Retrieved November 7th, 2007. http://www.americanchemistry.com/plastics/

9. Organisation for Economic Co-operation and Development. Working Group on Waste Prevention and Recycling. "Improving Recycling Markets". © OECD 2006.

10. "Process for waste plastic recycling" US Patent 6861568. Issued March 1st 2005

11. "Plastic recycling" US Patent 4493806. Issued May 11th 2004